Company Insight

Company Insight

Sponsored by Bühler Group

Meat Substitutes. Business opportunities along the protein value chain.

Image: copyright

T

oday, global food, feed, and mobility systems are causing global challenges. Bühler wants to turn these into business opportunities – and invite their customers, partners, scientists, and talents to jointly develop the solutions of tomorrow with them.

Food for the future – alternative proteins. Bridging the protein gap sustainably.

Today’s challenges.

Today, it is estimated that there are more than 800 million undernourished people in the world, and UNICEF states that undernutrition causes the deaths of around 3 million children a year. This can – and must – be stopped.

Without proper nutrition, children’s physical and cognitive growth, and lives, are at risk. But malnutrition is not just limited to the developing world. Poor diets and obesity are creating crises in higher income countries as well. At Bühler, we are developing new solutions to address these issues.

Finding new sources of protein

By the middle of this century, the food production must increase by approximately 70%, to produce an extra 265 million tons of protein to meet the demands of the world’s population. This will not be possible with our current food system. Therefore, finding new ways to work with more sustainable protein sources is essential to feed the world within our planetary boundaries.

Solving the problem together

At Bühler, we are developing new solutions to address the challenges of ‘the future of food’. To achieve this, we work with strong partners with the goal of providing more sustainable food.

Creating a sustainable food future.

There is a clear market shift towards a more plant-based diet that is motivated by health, sustainability and ethical concerns. The global market is still growing at double digit growth rates and will accelerate with plant-based meat reaching price parity with real meat.

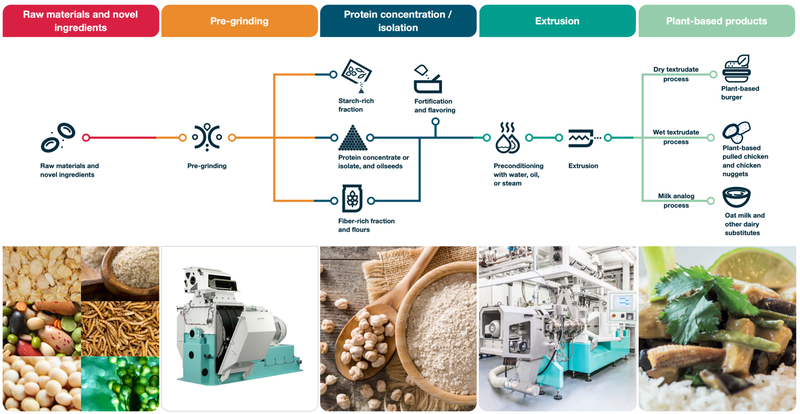

To benefit from this growth, we have developed complete solution from the protein source till the final products. From soy, oilseed, pulses to upcycling side streams or newer ingredients like microalgae or insects, we are leading the way in developing sustainable alternatives.

Our industrial-scale extrusion solutions enable the restructuring of plant proteins into high-quality, tasty meat and fish substitutes. With our latest innovations you can actively adjust the texture and mouthfeel of the product at the same time as producing at high capacity.

With our comprehensive customer service covering the entire life cycle of our protein lines, and our worldwide application centers, we are more than just service providers: We are partners for a lifetime. As a leading solution provider across the whole protein value chain (figure 1), we believe we have a responsibility, and an opportunity, to make a difference. This unique position enables us to accelerate your innovation, tailormade to your market of choice.

Revolutionary extrusion applications. Solutions for a wide range of innovative products.

Thanks to our market-leading expertise in extruded food and feed production, we have developed cutting-edge solutions to produce meat alternatives at high throughputs – up to 1000 kg/h in high moisture extrusion and even more in low moisture extrusion.

Extrusion is the core technology for a wide range of products. Inside the extruder barrels, heat and shearis applied to modify the structure of raw materials to generate fibrous textures and structures for meat like products, like a continuous pressure cooker. In just one machine ingredients can be mixed, hydrated, kneaded, and cooked under highly controlled conditions to ensure the right physical modifications and chemical reactions take place. Thanks to its modular design, a wide range of finished products can be produced depending on the conditions (e.g. moisture content, energy input, screw configuration) to obtain just the right structure for your application.

High-moisture extrusion and Protein Aeration Technology

The next generation of meat substitutes.

High-moisture extrusion with protein concentrates or isolates in conjunction with our patent pending Protein Aeration Technology is an efficient process to create meat-like textures similar to chicken, beef, fish or seafood. This is possible by injecting a gas inside the extruder and generating a microporous structure. Lighter colors, better mouthfeel and easy texture adjustments are combined with increased thickness due to the gas expansion at the end of the cooling die. The extruded product can be cut into chicken chunks, nuggets, pulled pork, fish fingers or into any other meat-like format.

Take a look at our technology and products

Contact details

Bühler AG

Gupfenstrasse 5

9240 Uzwil

+41 71 955 11 11