COMPANY INSIGHT

Sponsored by NETZSCH

Proven Excellence

For more than 60 years, NETZSCH has manufactured positive displacement pumps worldwide. Designed specifically for difficult pumping situations, NETZSCH pumps range in size from the industry’s smallest metering pumps to high volume pumps for applications in the oil and gas or mining industries.

With a production of over 55,000 pumps per year NETZSCH underlines the technology and market leadership, which it has gained thanks to the quality of the pumps and spare parts. It is guaranteed by the core competence and vertical manufacturing which we have built up over the many decades. With the worldwide implementation of common standards in accordance with DIN EN ISO 9001 in development and research, the company guarantees the highest quality at each of the five production sites.

NETZSCH has been supplying worldwide NEMO® progressing cavity pumps, TORNADO® rotary lobe pumps, NOTOS® multi screw pumps, macerators/grinders, dosing technology and equipment for custom built and challenging solutions for every applications.

NETZSCH is constantly further developing its comprehensive range of pumps with various designs, sizes, material options and accessories, which means it offers the appropriate pump for virtually every area of application. For example: beverages, biotechnical products, breweries, butter, chocolate, cosmetics, fermented dough, fish, fruits & vegetables, fruit juice, meat, mustard powder, pharmaceuticals, pomace, potatoes, soap stock, starch, sugar, syrup, tomato sauce, wine, yeast and much more.

Products shall keep fresh for a longer period of time and still maintain their original quality standard. Our pumps as the „driving force“ in your production process are a key ingredient of your product quality. We develop, manufacture and sell positive displacement pumps which ensure in all process stages a hygienic and smooth conveyance of high quality and shear-sensitive media: NEMO® hygienic and aseptic progressing cavity pumps and TORNADO® hygienic rotary lobe pumps. For each application your pump is individually laid out in flange & hopper design.

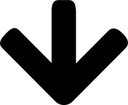

The TORNADO® rotary lobe pump T.Sano® with its oil-free design makes it ideal for food and pharmaceutical media. The self-priming, valveless, positive displacement pumps can be optimally customized to meet specific process and application requirements. They can be used for almost any media on intermittent, continuous or dosing applications.

A completely smooth housing attracts barely any dirt or dust. In addition to materials and cleanability of the pump area, great emphasis is placed on the outer contours of the components in the production process of the food and hygiene industries. To ensure that no dust can accumulate, the pump housing is designed without superfluous corners, edges and dead spaces. The pumps are also suitable for the CIP-/SIP-Process. For the CIP process, the entire system requires a cleaning fluid velocity of at least 1.5 m/s. As the pump reaches the required flow speed, it can also be used as a cleaning pump, i.e. the conveying and cleaning can be done by the same pump. All materials are in line with CIP and SIP processes.

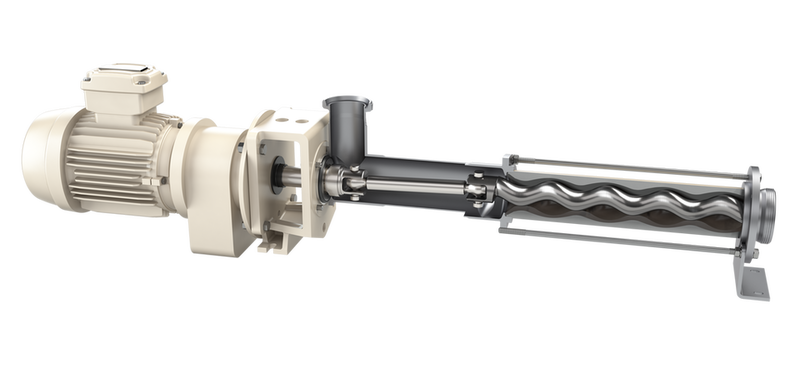

NEMO® hygienic and aseptic progressing cavity pumps are also especially designed to fulfill the high regulations required in the food industry. They bring benefits to the industry due to their continuous, pressure-stable, gentle and low-pulsation conveyance and due to their capability of precise dosing in proportion to speed. The block pump construction with flanged drive is particularly compact and economical to operate.

For the CIP/SIP processes again, the entire system requires a cleaning fluid velocity of at least 1.5 m/s and to facilitate this the NEMO® hygienic and aseptic progressing cavity pumps are equipped with additional cleaning ports and a bypass line. The position of the ports is optimized by using CFD studies to guarantee best flow and complete emptying of the NEMO® pump. In both the CIP and SIP processes the NEMO® pumps are operated intermittently. . All pump materials used are suitable for CIP and SIP processes.

NETZSCH takes special care towards the consumer, especially when processing critical media like food. Therefore, all NEMO® progressing cavity pumps and TORNADO® rotary lobe pumps as well as the corresponding accessories are manufactured in accordance with the nationally and internationally relevant manufacturing and hygiene standards and norms, from the 3-A Sanitary Standard to the specifications of the US Food and Drug Administration (FDA) and the Bundesinstitut für Risikobewertung (BfR). In addition, NETZSCH attaches great importance to resource-saving production and the use of certified materials at all production sites.