Robots remain expensive for consumers and businesses alike. During a cost-of-living crisis and high inflation, this will limit spending on innovation and research. However, those products which can offer convenience and have proven use cases will be worth the expense.

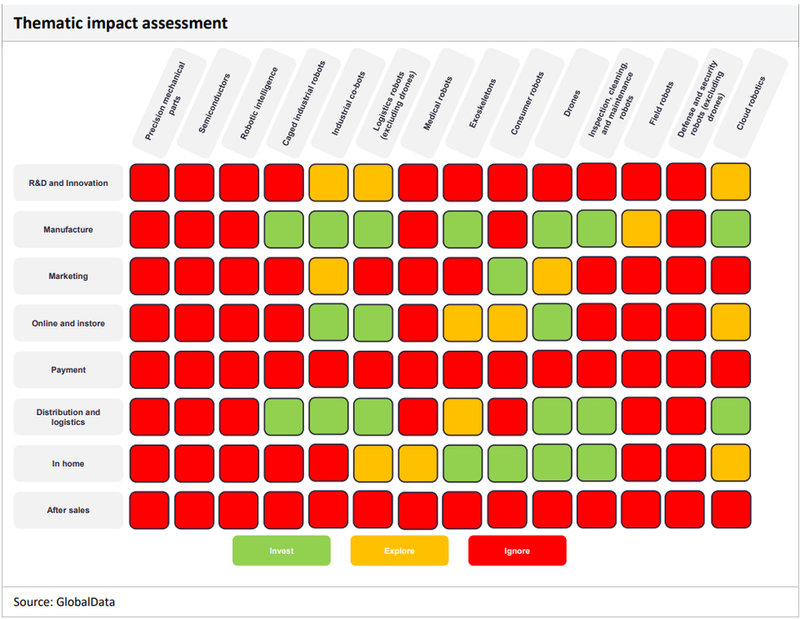

The matrix below details the areas in robotics where consumer goods companies should be focusing their time and resources. We suggest that FMCG invest in technologies that are shaded in green, explore the prospect of investing in technologies shaded in yellow, and ignore areas shaded in red.

Most use cases for robots in consumer lie in manufacturing, distribution, and logistics. However, there are some exciting use cases in home robots, as consumers look to robots for convenience and assistance. The average consumer is also more comfortable with technology and uses some form of tech in their everyday lives, leading to more in-home applications for robotic technology.

Industrial caged and co-bots and logistics robots have been used in warehouses and factories in production lines for decades, aiding in the manufacturing, logistics, and distribution processes for consumer companies.

Consumer companies need to quickly respond to changes in demand from consumers and therefore changes in production. Products and workspaces are also adapting to ecommerce, fast delivery capabilities, as well as direct-to-consumer models.

Increased use of robots allowed consumer goods companies to comply with social distancing guidelines during the pandemic and limit the number of people needed in the workspace. Post-pandemic, health and safety issues are at the forefront of public consciousness.

Inspection, cleaning, and maintenance robots, both in factories and warehouses, as well as in-store, help to keep spaces clean and well-managed to limit workplace hazards and risks.

At home, use cases for robots are shifting from being dominated by cleaning robots, to personal assistants carrying out social functions and performing tasks around the house to assist their users.

The convenience that robots can offer, from the delivery process to in-home appliances, will result in more consumers purchasing them, an area of growth that cannot be ignored for consumer goods vendors. Household care consumer companies (selling cleaning products, etc.) will look to offer more robotic solutions for a more technology savvy consumer who is looking for more convenience.

Cloud and artificial intelligence technologies enable robots to become more sophisticated and to perform a wider variety of functions. It offers new possibilities in consumer robotics that go beyond robot vacuum cleaners.

Robots can connect to other devices and smartphone applications to perform a wider range of functions to bring more convenience for business operations and the consumer in the home. In this sense, smart technologies such as AI and robotics are laying the groundwork for smart consumer devices and creating smart homes and smart cities, a trend that will continue in the coming years.

How robotics helps resolve the challenge of convenience

Robots, coupled with smart technologies, offer more efficiency both in the delivery and purchasing process of products. Consumer companies are laying the groundwork for developing a network of drones capable of safely delivering products to consumers speedily and across a larger distance.

This is Amazon’s ambition as it introduced its Prime Air drone in June 2022. Prime Air is based on a smart and advanced sense-and-avoid system that helps to travel greater distances safely and consistently. As drones and autonomous mobile vehicles mature, they will offer greater convenience to consumers who opt to shop online and get products delivered to their homes.

In terms of the products themselves, consumers are increasingly purchasing smart robot devices to help with in-home tasks. For example, in 2021 Segway developed a robot mower that uses GPS technology to move in systematic mowing patterns and precise positions.

Users can use a smartphone application linked to the robot to define the areas to be mowed. In June 2021, a Canadian robotics company launched an automated cooking robot connected to an application that was independently capable of performing all the steps of a basic recipe.

How robotics helps resolve the challenge of health & wellness

Robotics limit touchpoints in the home and workplace to halt the spread of infections and avoid microbiological impurities. This is an important factor to consider in the manufacturing process, especially when it comes to handling food products.

German robotics company Kuka produced a hygiene robot called KR Delta to perform pick and place tasks in consumer goods, food, and packaging. It is made of corrosion-resistant steel, meets German food commodities law and US FDA food standards, and is expected to work in hygienically sensitive areas where it comes in direct contact with food items, electronic components, or medicines.

In 2022, the annual Consumer Technology Association conference predicted that the next big trend in consumer robots were UV-C disinfecting robots, appealing to consumers who wish to keep their home more hygienic.

For example, Ecovacs, a large consumer robotics company, developed an AI-powered vacuum cleaner named DEEBOT T10 capable of memorizing and mapping out your home floor plan and reducing the amount of time needed to vacuum the floors.

Wearable tech robots will also assist consumers who wish to improve their health through fitness. In 2021 Hong Kong-based company Enhanced Robotics developed Sportsmate 5, an exoskeleton piece of wearable tech designed to boost an individual’s physical performance. It is the first consumer exoskeleton as its predecessors were used to train soldiers or used in medical cases to assist people who suffer from mobility issues.

How robotics helps resolve the challenge of disrupted supply chains

Within supply chain management, robotics technologies are being used to maximize and optimize production efficiencies. For example, robots can be used in manufacturing to ensure standardized and streamlined processing or in picking and packing to reduce human error.

Robots can be easily scaled up and modified to adapt to supply changes and provide a solution to warehouse labour issues and increase productivity. We will see a rise in fully automated or semi-automated production lines to increase productivity and enhance performance in warehouses and on the factory floor.

Robots can perform strenuous and repetitive tasks, freeing up workers to perform other more high-skilled, demanding tasks. These processes use mainly collaborative robots or co-bots. In stores, robots can perform routine tasks such as counting inventory, updating and printing out price labels, and, in the future, interacting with customer queries.

How robotics helps resolve the challenge of ESG

Increased use of robotics is a double-edged sword for health and safety issues. On one hand, robots can carry out tasks that are heavy and dangerous for humans to perform. On the other hand, workers risk physical injury through unanticipated contact and a lack of understanding of how the machinery works. However, if installed correctly and with proper training, robots can ease the burden on workers and limit the amount of heavy, dangerous tasks they perform.

In terms of reducing a consumer goods company’s carbon footprint, drones have become increasingly popular in delivering products to consumers in the last-mile process of consumer goods. Transportation via drones allows companies to deliver goods efficiently and sustainably without the by-product of CO2, giving consumer goods companies a better chance of meeting targets for carbon neutrality by 2050.

How robotics helps resolve the challenges around the future of work

Mobile Robots (AMRs) and Automated Storage and Retrieval Systems (ASRS) can revolutionize the effectiveness and speed of fulfilment centres and warehouses globally, easing the burden of repetitive, strenuous tasks for workers, freeing them up to perform more complex tasks to help make work more efficient.

Static or caged robots that perform repetitive tasks in one location are being swapped for uncaged collaborative robots that move around production rooms independently, often in tandem with physical workers.

American technology company Berkshire Grey has launched a robotic pick and pack (RRP) solution for e-commerce fulfilment, automating the picking and packing of items directly from inventory containers into outgoing customer shipping packages. This complements the use of drones in the delivery stage.

These robots also help to automate the workplace and improve efficiency. An Ocado Group warehouse in southeast London, known as the ‘Hive’, houses around 2,300 robots capable of gathering around 58,000 different individual products within a grid and packaging them to order for consumers who place orders online. Ocado claims it can have stock in the warehouse and out again from suppliers, and into a delivery van, in just five hours, thanks to the use of robotics.

Consumer goods companies will need robots to enable direct-to-consumer processes. Automation increases output at their e-commerce fulfilment operations while dealing with severe manpower shortages. The quicker and more efficient the manufacturing and logistics processes are, the better-equipped consumer companies will be in meeting consumer demand.

GlobalData, the leading provider of industry intelligence, provided the underlying data, research, and analysis used to produce this article.

GlobalData’s Thematic Intelligence uses proprietary data, research, and analysis to provide a forward-looking perspective on the key themes that will shape the future of the world’s largest industries and the organisations within them.