Automation

Rise of the robots: will tech revolutionise the QSR sector?

Though many still view it as a futuristic notion, the introduction of robots in the quick service restaurant sector is gaining momentum. Peter Nilson speaks to Barney Wragg, CEO of Karakuri, to find out how the company is gearing up to disrupt the sector with robotics and AI.

Self-service checkouts are, for many, the norm nowadays. Though first developed in the 1960s, it took until the 1990s for them to begin to proliferate. Some have predicted that by 2025 there will be over 1 million self-service checkouts installed globally.

The concept of completing a trip to the local supermarket without having any human interaction is not as alien as 20 years ago.

For those who work in highly urbanised environments, the daily trip to grab a sandwich during their lunch breaks is a quick, solitary experience. Grab, queue, scan and tap.

The benefits of self-service checkouts seem self evident - retailers can serve more customers whilst hiring fewer staff. Customers, in theory, have a faster, easier experience in-store.

But what if this same logic was applied to the experience we have when visiting a quick service restaurant (QSR)?

An emerging technology for QSR

As seen with the introduction of self-service checkouts, many of us have a novel, curious reaction when we are confronted with a machine in place of a person. “I think we, as humans, have peculiar reactions to machines,” says Barney Wragg, CEO and co-founder of Karakuri, a UK-based robotics startup. “But we also, peculiarly, like a machine that does something very specific.”

Karakuri, launched in earnest in 2019, is looking to shake things up in the QSR sector through its robotic solutions. The company’s vision is to replace – or augment – staff in QSR locations with robots in order to handle the workload of a restaurant more efficiently.

“There's been a lot of automation in food production and food processing for many years, but when you get to the restaurant-consumer level, things are still very much done by hand,” explains Wragg. “A lot of time is spent serving food, taking things that have been prepared and putting them in the right format or in the right combination to hand over to the customer.”

This may sound counter-intuitive, as traditionally it would be argued that machines are best placed in the kitchen to help with food preparation. However, as Wragg correctly points out, for the QSR sector, food preparation can happen throughout the day, but it’s the lunch-rush that causes the largest strain on staff. “They get this massive peak of demand over a 90 minute to two hour period, and they need a huge amount of labour to be able to service that demand, putting those things together”

The benefits of automation

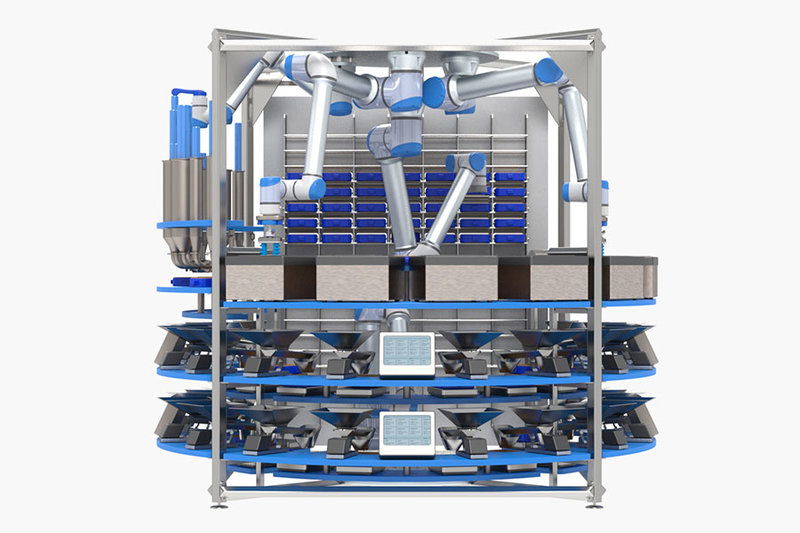

Karakuri’s solution to this problem is the DK-One, which uses a combination of robotics and AI to serve meals, by taking the pre-prepared ingredients and assembling them into the final product.

According to Wragg, who worked for many years at British semiconductor giant ARM Holdings, the machine can operate far more efficiently than a human worker.

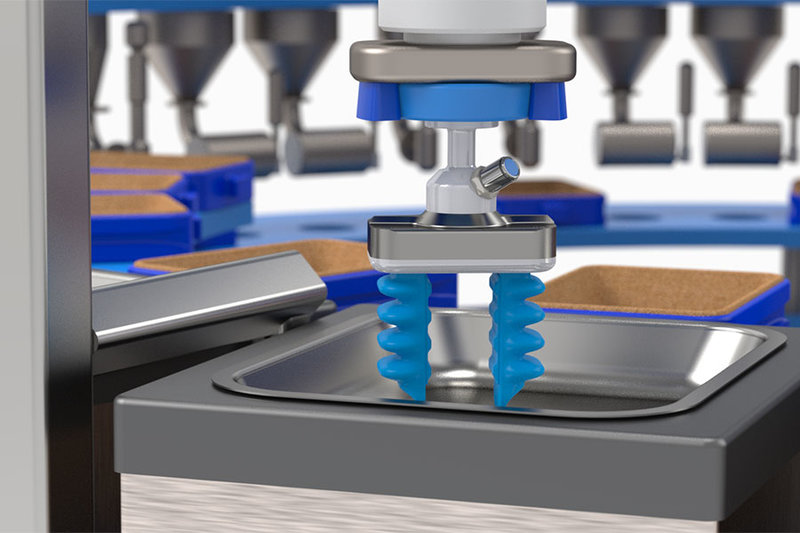

"Automation can be very accurate in its portion control, it's very deterministic in the time it takes to give a portion of it. So you can smooth out that labour requirement in the restaurant," he says.

”It's not unusual to be seeing at the peak time, as we're going through testing now, four or five orders happening in parallel.”

This achieves an efficiency that is greater than than most people could manage consistently throughout a lunch rush.

“It really depends on the nature of the specific orders and what's going on with the profile of the order. The machine uses its intelligence to create the optimal routing for a particular meal through the system, rather than it being a traditional linear conveyor.”

Karakuri’s DK-One. Image: Karakuri

And aside from the day to day operations, Karakuri believes firmly that the MK-1 can streamline business operations, especially for QSR chains.

“How do you better understand what your input costs should be? How do you really make sure you're ordering the right amount of stuff, preparing the right amount of stuff, and then you're portioning and selling the right amount of stuff?” asks Wragg.

“That's really important for us. The machine is very accurate at portioning and it can be very variable in portion sizes, staying very accurate. Which means at the end of the service, you know exactly what is sold, and to how many customers.”

The two big things that our system does, is to allow you to optimize your labour usage and help you get a real grip on your input costs.

This is where the less intrusive, but arguably more important part of the DK-One comes into play for businesses. By tracking this type of data, restaurants will have a better knowledge of what they should be ordering and when certain products are in higher demand

“As you do that over a period of time, you can build those patterns,” says Wragg. “You could build analysis so you can profile your whole workstream and materials usage, your ingredients usage, much better because you're collecting data all the time.”

This type of information is vital for locations where consistency is paramount, in spite of any potential staff turnover that could lead to a loss of knowledge.

“When you look at the big chains, the turnover of staff that they've had has meant that they’ve very often got restaurant managers going in with little or no experience, and being asked to make very important decisions about what they should be ordering for delivery,” Wragg explains. “It might be three days, five days, 10 days out, but they don't have that knowledge.”

Being able to draw on previous data, in this context, would be a huge boon, and naturally beneficial to both customers and businesses, avoiding food wastage and ensuring products are available during periods of high demand.

“The two big things that our system does, is to allow you to optimise your labour usage and help you get a real grip on your input costs,” Wragg says.

Coronavirus: the elephant in the room

It can’t be denied that there will be customers who will have no appetite for the idea of a machine preparing their food. However, we use machines to prepare food every day, both at home and in professional kitchens, so how is it different if a machine combines the different parts of a meal into the final thing?

"There's a school of thought that says food is a very human thing. It's artisanal. Something that, you know, you want it to be made by humans,” says Wragg.

"On the other side of it was, even before Covid, people who would be excited by seeing the machine and think it's very hygienic, and that it's giving them very accurate things.”

As Wragg correctly points out, the Covid-19 pandemic has brought with it increasing concerns over food safety, and in turn more businesses are looking for solutions. “We've seen an awful lot more interest from people saying: okay, that's really clean.”

And the food sector has been hugely impacted due to lockdown. But as businesses start to re-open, many are far more open to new technology that can help them in terms of hygiene.

“Everybody's in flux at the moment,” says Wragg. “I think that whatever happens, I think what's going to stay with us post-covid is a longer term concern about hygiene and potential cross-contamination.

“I think the whole thing has made us much more aware of personal hygiene and contact in general, and I think that will be reflected in the way that you see restaurants operate”

New technology, old problems

If the benefits are so great, why aren’t businesses jumping at the opportunity? Well, in part, they are. Online retailer Ocado has invested £7m in Karakuri, and the startup plans to launch its first test in Ocado’s staff canteen by the end of this year, with more tests with different companies planned for 2021.

But as with any emerging technology, the usual problems of cost and development stand in the way. And make no mistake, this is still very much an emerging technology. “This is a massive industry. There's a growing number of companies in the space all the time, but we're all tiny minnows at the moment.”

The DK-One’s Robotic arms. Image: Karakuri

Tiny minnows, perhaps, but minnows that have huge potential to grow – if they receive the right investment. Wragg says that globally, his best estimate is that this is a $3.5-4tn industry, with "enormous opportunities", but also acknowledges that “the biggest challenge is investment”.

“Outside of the US, high-risk technology investment is harder to come by than it is in the US. It's not impossible, and we've been very lucky so far," says Wragg. “But we really are at the leading edge of what's possible. I think everything is there that the building blocks of what's needed to drive this particular revolution are all in place.”

“It's embryonic,” admits Wragg. “That's what's exciting for me, it's a new space. And there's lots of things that need doing in that space across all the different multitude of food processing problems around there.”

So if we come back to the self-service checkout, there are parallels to be drawn. Faster service and the ability for businesses to serve more customers are the obvious. But remember, it took some decades for self service checkouts to become the norm.

Though things seem promising, it may be some time until customers find themselves full of that sense of curiosity as they’re confronted with a new machine, doing an old job.

”We're at the beginning of what's going to be another 20 or 30 years or more of development in those technologies,” Wragg predicts optimistically. “We’re just starting to see it come through.”