Stainless-steel washdown sensors

click to expand

Level mesurement in hygienic applications

click to expand

Contamination prevention

click to expand

Tracing individual item in real time

click to expand

Working together as equals - sensor solutions for robotics

click to expand

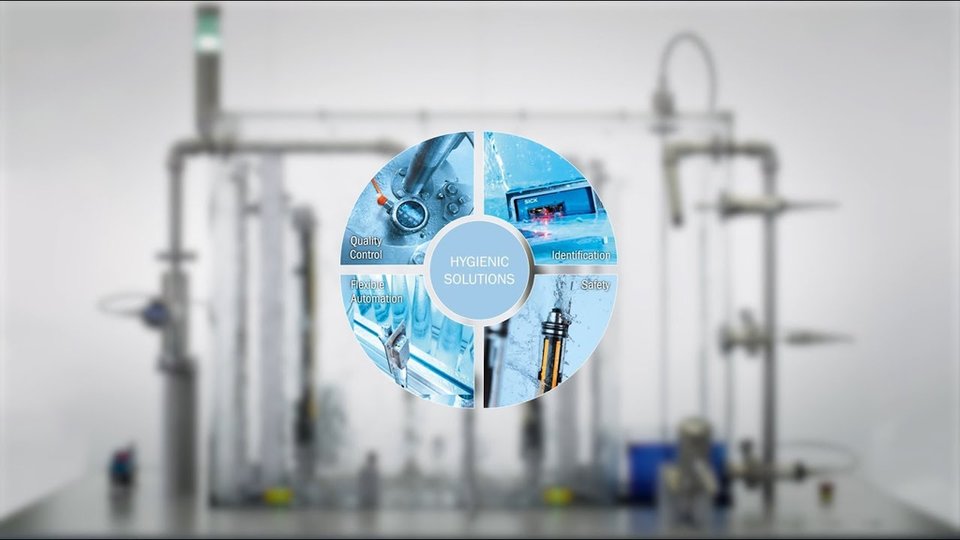

Achieving more with SICK intelligent solutions

Achieving more with SICK intelligent solutions

Stainless-steel washdown sensors

A hygienic system design – and in particular hygienic automation components – can minimize the contamination risks for products and communication risks for manufacturers: Germs and bacteria do not stand a chance against stainless-steel sensors and system solutions from SICK.

Learn more >

Contamination prevention

Hygiene-compliant sensors “shine” not only on account of their stainless-steel housing but also as a result of numerous other measures that guarantee the best possible chemical and thermal resistance as well as impermeability.

Learn more to prevent product recalls >

Tracing individual item in real time

Product labeling using RFID technology is opening up an increasingly wide range of applications, primarily as a result of costs dropping and processor technologies becoming more efficient. Vision sensors which record 1D bar codes and 2D codes provide additional food for thought when it comes to Industry 4.0. The combination of image and bar code recognition – reading a code while simultaneously checking against a stored image – ensures that the right product goes into the right package.

Complex label inspections >

Working together as equals - sensor solutions for robotics

For all challenges in the field of robotics: Robot Vision, Safe Robotics, End-of-Arm Tooling, and Position Feedback, SICK intelligent solutions are tailor to our customer needs and ensure the safety of operators.

Robotics solutions >

Level measurement in hygienic applications

The LFP Inox is a hygienic level sensor for liquids using TDR technology – a process for determining the time of flight of electromagnetic waves. The use of FDA-compliant materials in an EHEDG-certified design means that the LFP Inox can be relied upon for optimum and unrestricted cleaning, even in applications with the most stringent hygiene requirements.

Find out more >

A hygienic system design – and in particular hygienic automation components – can minimize the contamination risks for products and communication risks for manufacturers: Germs and bacteria do not stand a chance against stainless-steel sensors and system solutions from SICK.

Learn more >

Hygiene-compliant sensors “shine” not only on account of their stainless-steel housing but also as a result of numerous other measures that guarantee the best possible chemical and thermal resistance as well as impermeability.

Learn more to prevent product recalls >

Product labeling using RFID technology is opening up an increasingly wide range of applications, primarily as a result of costs dropping and processor technologies becoming more efficient. Vision sensors which record 1D bar codes and 2D codes provide additional food for thought when it comes to Industry 4.0. The combination of image and bar code recognition – reading a code while simultaneously checking against a stored image – ensures that the right product goes into the right package.

Complex label inspections >

The LFP Inox is a hygienic level sensor for liquids using TDR technology – a process for determining the time of flight of electromagnetic waves. The use of FDA-compliant materials in an EHEDG-certified design means that the LFP Inox can be relied upon for optimum and unrestricted cleaning, even in applications with the most stringent hygiene requirements.

Find out more

For all challenges in the field of robotics: Robot Vision, Safe Robotics, End-of-Arm Tooling, and Position Feedback, SICK intelligent solutions are tailor to our customer needs and ensure the safety of operators.

Robotics solutions >