Market Focus

Fresh Ideas:

Microwave-Assisted Thermal Sterilisation Food Processing Technology

MATS technology is attracting interest from foodservice operations as well as food and beverage companies. Using research from an upcoming GlobalData report, Eloise McLennan rounds up the key features of the technology

A new method of sterilisation is creating a buzz among packaged food brands. Microwave-assisted thermal sterilisation (MATS) is a new food processing technology that uses long-wavelength microwave energy together with heat to sterilise packaged food.

The technology has been hailed as a potential game-changer for packaged food manufacturers as the MATS process uses less time and heat than the conventional retort method, which means that fewer nutrients are damaged due to long periods of exposure to high-temperatures. For food brands, this is likely to be an enticing advantage, as minimising damage reduces the need for food additives, preservatives and excess sodium.

View GlobalData Reports

GlobalData innovation insights director Tom Vierhile offers a detailed insight into the potential of MATS in the upcoming report ‘ForeSights: Microwave-Assisted Thermal Sterilization Food Processing Technology’. Drawing from findings detailed in the report, we take a look at the key features of MATS, and how industry players could benefit from this unconventional approach to sterilisation.

The process of sterilisation: MATS vs. Retort

Food sterilised using the traditional retort method requires manufacturers to place the product into a pressurised cooker, where it is exposed to high temperatures of approximately 121oC for up to one hour.

The process often results in the food becoming damaged from exposure to heat, and consequently, brands frequently use salt, flavour, texture and colour enhancers to compensate for the damage.

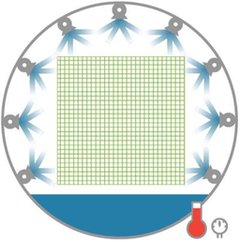

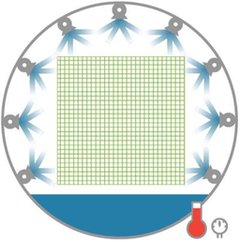

Image of Retort food processing

In contrast, MATS uses a combination of long-wavelength microwave energy and pressurised hot water to sterilise packaged food. This method eliminates micro-organisms and pathogens that may impair the quality of the food.

MATS involves quickly immersing packaged food in pressurised hot water and then heating it with microwave energy at a frequency of 915 megahertz for ten to 15 minutes, a fraction of the time required for conventional sterilisation methods.

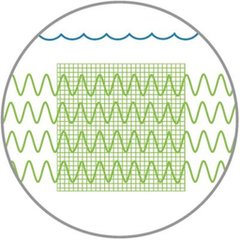

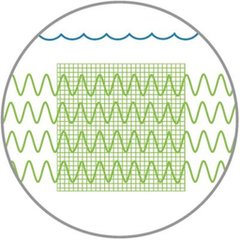

Image of MATS processing

MATS: a food sterilisation technology with military roots

The underlying technology that led to the development of MATS was established by food engineering scientists at Washington State University in the US. The project was supported by a consortium of private companies within the food industry and the US Department of Defense.

Military service members are most likely to have encountered microwave-assisted thermal technologies, as packaged meals such as the military’s ready-to-eat meals are produced using this type of technology. These meals are often carried and consumed on the battlefield, which means that the product needs to be able to remain unspoiled without being refrigerated. As such, microwave-assisted thermal technology provides a functional solution to the issue of eating meals in a variety of unconventional and remote environments.

According to the GlobalData report, MATS is currently the only microwave sterilisation process recognised by the US Food and Drug Administration. A decade after the first patents for the technology were filed, in 2016, the first commercial-scale MATS system was unveiled by 915 Labs, a US-based food processing and packaging technology company, which has an exclusive license to the MATS technology.

Food preservation with MATS

Heat-sensitive food, such as eggs and dairy products, is likely to benefit from a sterilisation method that requires less processing time. MATS has been successfully used to process a number of such products, including seafood and pasta products, and according to 915 Labs, culinary experts have been using MATS systems to create recipes that feature nutrient-rich ingredients which are high in protein, fats and fibre.

MATS is especially well suited for these types of food:

Benefit: Enhanced taste and texture

Conventional thermal processing kills pathogens, however, with methods that use high levels of heat manufacturers also run the risk destroying nutrients and compromising the colour and flavour of foods.

In contrast to processing methods such as retort, MATS requires less heat, pressure and time to sterilise food during processing, which means that the nutrients and flavours remain intact. Moreover, food that has been processed using MATS is quickly cooled once it has emerged to minimalise heat exposure and preserve the food.

Benefit: Meeting clean-label demands

Food manufacturers using MATS don’t have to rely on the use of artificial preservatives chemicals, or texture-enhancing additives, as the technology sterilised food in a way that preserves the natural nutrients that already exist in the product. MATS also requires far less sodium than traditional processing methods.

Food recipes that are processed using MATS start with 50% less sodium that traditional retort recipes. This can be particularly appealing to health-focused shoppers, and brands can leverage the use of a ‘clean’ sterilisation method to target the demand for clean-label food products.

Benefit: Room temperature storage

MATS technology enables packaged food to be stored at room temperature for long periods of time, which means that consumers can keep meals in a pantry as opposed to a refrigerator or freezer. This could potentially limit the amount of food that consumers waste, as MATS processed food can be store at room temperature for up to one year.

Shelf-stable storage may have a significant impact on supply chain elements related to direct-to-consumer food and beverage marketing. Specifically, MATS may be a prime solution for internet meal delivery companies. Currently, such operations ship perishable meals in packaging materials that are required to maintain chilled or frozen temperatures over a long period of time to ensure the safety of products.

A new method of sterilisation is creating a buzz among packaged food brands. Microwave-assisted thermal sterilisation (MATS) is a new food processing technology that uses long-wavelength microwave energy together with heat to sterilise packaged food.

The technology has been hailed as a potential game-changer for packaged food manufacturers as the MATS process uses less time and heat than the conventional retort method, which means that fewer nutrients are damaged due to long periods of exposure to high-temperatures. For food brands, this is likely to be an enticing advantage, as minimising damage reduces the need for food additives, preservatives and excess sodium.

View GlobalData Reports

GlobalData innovation insights director Tom Vierhile offers a detailed insight into the potential of MATS in the upcoming report ‘ForeSights: Microwave-Assisted Thermal Sterilization Food Processing Technology’. Drawing from findings detailed in the report, we take a look at the key features of MATS, and how industry players could benefit from this unconventional approach to sterilisation.

The process of sterilisation: MATS vs. Retort

Food sterilised using the traditional retort method requires manufacturers to place the product into a pressurised cooker, where it is exposed to high temperatures of approximately 121oC for up to one hour.

The process often results in the food becoming damaged from exposure to heat, and consequently, brands frequently use salt, flavour, texture and colour enhancers to compensate for the damage.

Image of Retort food processing

In contrast, MATS uses a combination of long-wavelength microwave energy and pressurised hot water to sterilise packaged food. This method eliminates micro-organisms and pathogens that may impair the quality of the food.

MATS involves quickly immersing packaged food in pressurised hot water and then heating it with microwave energy at a frequency of 915 megahertz for ten to 15 minutes, a fraction of the time required for conventional sterilisation methods.

Image of MATS processing

MATS: a food sterilisation technology with military roots

The underlying technology that led to the development of MATS was established by food engineering scientists at Washington State University in the US. The project was supported by a consortium of private companies within the food industry and the US Department of Defense.

Military service members are most likely to have encountered microwave-assisted thermal technologies, as packaged meals such as the military’s ready-to-eat meals are produced using this type of technology. These meals are often carried and consumed on the battlefield, which means that the product needs to be able to remain unspoiled without being refrigerated. As such, microwave-assisted thermal technology provides a functional solution to the issue of eating meals in a variety of unconventional and remote environments.

According to the GlobalData report, MATS is currently the only microwave sterilisation process recognised by the US Food and Drug Administration. A decade after the first patents for the technology were filed, in 2016, the first commercial-scale MATS system was unveiled by 915 Labs, a US-based food processing and packaging technology company, which has an exclusive license to the MATS technology.

Food preservation with MATS

Heat-sensitive food, such as eggs and dairy products, is likely to benefit from a sterilisation method that requires less processing time. MATS has been successfully used to process a number of such products, including seafood and pasta products, and according to 915 Labs, culinary experts have been using MATS systems to create recipes that feature nutrient-rich ingredients which are high in protein, fats and fibre.

MATS is especially well suited for these types of food:

Benefit: Enhanced taste and texture

Conventional thermal processing kills pathogens, however, with methods that use high levels of heat manufacturers also run the risk destroying nutrients and compromising the colour and flavour of foods.

In contrast to processing methods such as retort, MATS requires less heat, pressure and time to sterilise food during processing, which means that the nutrients and flavours remain intact. Moreover, food that has been processed using MATS is quickly cooled once it has emerged to minimalise heat exposure and preserve the food.

Benefit: Meeting clean-label demands

Food manufacturers using MATS don’t have to rely on the use of artificial preservatives chemicals, or texture-enhancing additives, as the technology sterilised food in a way that preserves the natural nutrients that already exist in the product. MATS also requires far less sodium than traditional processing methods.

Food recipes that are processed using MATS start with 50% less sodium that traditional retort recipes. This can be particularly appealing to health-focused shoppers, and brands can leverage the use of a ‘clean’ sterilisation method to target the demand for clean-label food products.

Benefit: Room temperature storage

MATS technology enables packaged food to be stored at room temperature for long periods of time, which means that consumers can keep meals in a pantry as opposed to a refrigerator or freezer. This could potentially limit the amount of food that consumers waste, as MATS processed food can be store at room temperature for up to one year.

Shelf-stable storage may have a significant impact on supply chain elements related to direct-to-consumer food and beverage marketing. Specifically, MATS may be a prime solution for internet meal delivery companies. Currently, such operations ship perishable meals in packaging materials that are required to maintain chilled or frozen temperatures over a long period of time to ensure the safety of products.