Leading provider of sensor-based food sorting machines

TOMRA SORTING FOOD

With more than 5,000 of its systems installed at food growers, packers and processors worldwide, TOMRA Sorting Food is a global market leader. The company provides high-performance optical sorters, peeling and process analytics systems for nuts and seeds, dried fruits, potato products, fruits, vegetables, meat and seafood. Its sorting machines ensure optimal quality and yield, resulting in increased productivity, throughput and an effective use of resources.

Its distinct development of advanced technologies supported by excellent customer care to deliver increased yields, improved food safety and enhanced profitability is entirely unified across the company. This proposition sits at the heart of TOMRA Sorting Food and ensures the company continuously improves for the benefit of its customers.

“TOMRA Sorting Food offers sorting equipment for a multitude of food applications, from fresh whole products to processed food, from farm to fork.”

SENSOR TECHNOLOGY

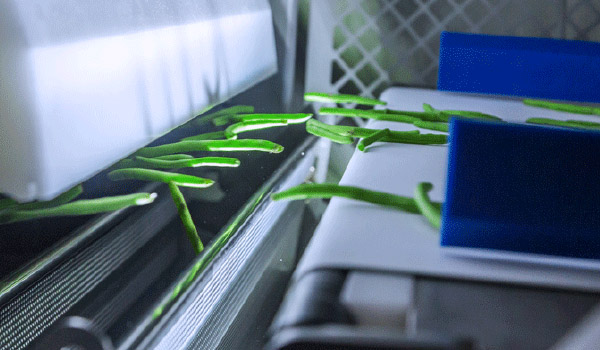

TOMRA Sorting Food’s focus on research and development has enabled it to develop a range of innovative sorting machines which are able to detect and remove the smallest of defects and foreign material from production lines. Its range of sensor-based solutions transforms how the world optimizes its precious resources, allowing for sustainable growth and maximum profit while reducing environmental impact.

TOMRA Sorting Food’s machines use a variety of sensors which go far beyond the common use of color cameras. Near Infra-Red (NIR) spectroscopy enables an analysis of the molecular structure of a product whilst x-rays, fluorescent lighting and lasers measure the elemental composition of objects. The internal composition and surface structure of objects can also be analyzed to determine good or bad produce.

“TOMRA Sorting Food’s machines are not only the most efficient way to sort products; they are also a smart investment.”

TOMRA’S FOOD SORTERS: SMART INVESTMENTS

Genius optical belt sorting machine

The Genius optical belt sorting machine uses a combination of sorting technologies to meet the high food safety requirements of the food industry and individual food processors.

The sorter uses air ejectors to separate good and bad produce and can be tailored to individual customer requirements, taking into consideration their unique needs. The machines require little maintenance and can handle a high volume of produce at any one time.

The Genius can sort a multitude of foods including potato products, nuts, fruit and vegetables. With high resolution cameras and lasers, it offers a combination of inspection technologies in different inspection zones, achieving unequalled sorting performance.

For operators, the sorting machine brings multiple benefits. Its graphical user interface enhances ease of use and its high volume abilities means processing is faster, more effective and efficient without compromising food safety and quality.

Nimbus BSI free fall sorting machine

The Nimbus BSI (Biometric Signature Identification) is a breakthrough for nuts and raisin processors. With a combination of various sorting technologies, the Nimbus free fall sorting machine meets the continuous high requirements of the food industry and individual processors for safe and excellent food quality by removing unwanted material.

The biometric signature identification (BSI) technology detects the biometric characteristics of nuts, dried fruits and other commodities. The BSI technology, which was developed in-house by the company’s own experts, is the next generation of spectral imaging, introduced to identify the material’s unique fingerprints.

Halo sensor-based optical food sorter

The Halo sensor-based optical food sorter is an ideal solution for potato and vegetable processors and packers who want to make their operations leaner and are looking for a return on investment using advanced sorting technology.

A high performance machine, the Halo is able to sort according to size and quality. The Halo offers excellent throughput and capacity, without losing consistency and accuracy, boosting processors’ lines and overall efficiency.

The Halo’s ability to consistently detect and remove potatoes for example, with unwanted greening defects, blemishes and damage means higher yields and a safer, higher quality final product going to the packing line or onto further processing. Moreover it has the ability to detect, classify and remove subtle defects into a separate stream for second grade pack or further rework in the processing line.

Click here to read more about TOMRA’s success stories.

For more information on TOMRA Sorting Food and the various other food sorting machines available, visit www.tomra.com/food