360° solutions for your Food & Beverage plant

Kurita is one of the global market leaders in industrial water and process treatment. With more than 70 years of experience, we provide you with state-of-the-art solutions, tailored to the specific needs of your water systems. Kurita offers an innovative all-in-one solution for the full water cycle of your food & beverage plant, which will help you to save water and energy and improve the productivity of your plant.

Check out one of our latest product innovations specially designed for the Food & Beverage industry:

Check out one of our latest product innovations specially designed for the Food & Beverage industry:

Powerful rinsing agent

Shiny surfaces on containments

Prevention of oil, fat and scale deposits

Supports drying effect

Excellent top-up product for your pasteurizer and sterilizer treatment

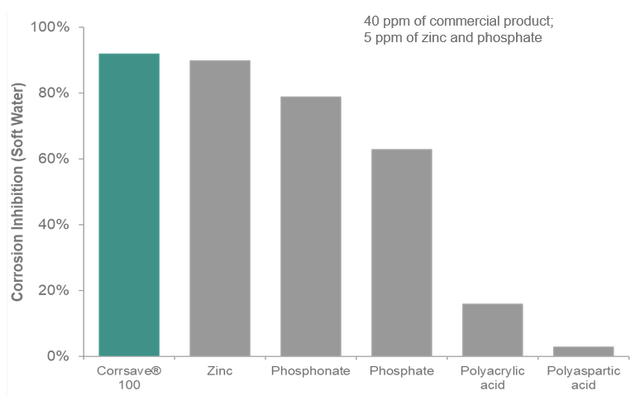

F&B Cooling Water Treatment: Corrsave® 100

- Environmentally friendly corrosion inhibition

- Based on natural and renewable organic acids

- High performance compared with current state-of-the-art corrosion inhibitors

Low phosphate - contribution to comply with stricter limits

Readily biodegradable

Reduction of corrosion and pitting

Synergistic effect with Zn/phosphate treatment

NSF White BookTM listed for cooling water in and around food processing areas

See more

The whole package with incredible performance

- Excellent corrosion properties on steel

- Stable corrosion inhibition in all common CW pH's

- Excellent chlorine stability

- Corrosave® can be applied with hypochlorite

F&B Cooling Water Treatment:

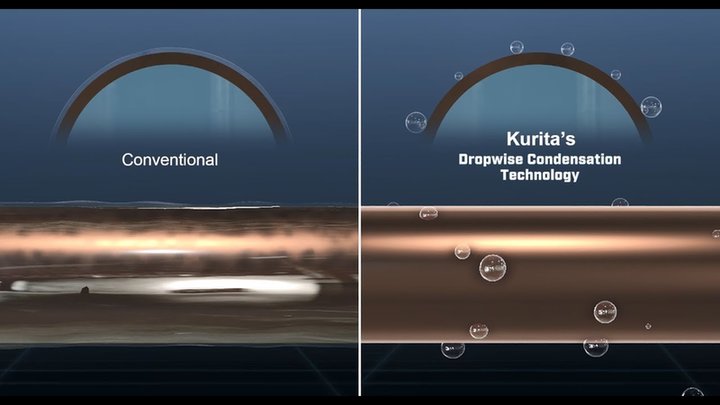

Kurita Dropwise Condensation Technology

improved productivity

increased heat exchange rate

reduced steam consumption rate

Learn more about all-in-one water treatment solutions for your F&B plant

Learn more about Avista membrane treatment solutions - a global brand of Kurita

Kurita Europe

Theodor-Heuss-Anlage 2

68165 Mannheim

Germany

contact an expert to learn more

Increases productivity and boosts heat transfer efficiency in industrial systems and heat exchangers.

Innovative technology to improve heat transfer efficiency in industrial systems such as heat exchangers, condensers, and dryer cylinders in the paper production process.

Can be applied without applying any additional system equipment.

Covers the entire surface with a water repellent film preventing water from forming an isolating layer. The result is a significant improvement of heat transfer efficiency leading to reduced steam consumption, less CO2 emission, and increased productivity.

Sustainable technology leads to a reduction of carbon dioxide emission supporting the development of an eco-friendly society.

Kurita Group

@KuritaGlobal

Kurita Global